CAM2® 8-Axis Quantum Arm is a complete metrology solution, with and without contact, which allows operators to significantly speed up and simplify measurement and scanning operations. It is the ideal tool for inspection and quality control, and is the perfect solution for comparison with CAD data, rapid prototyping, reverse engineering and 3D modeling of free-form surfaces. The scanning probe uses blue laser technology, which has a shorter wavelength than red or green lasers and provides better scanning results with higher fidelity. This means that even the finest details can be captured, as well as the ability to scan dark and shiny surfaces is significantly improved.

CAM2® 8-Axis Quantum Arm is a complete metrology solution, with and without contact, which allows operators to significantly speed up and simplify measurement and scanning operations. It is the ideal tool for inspection and quality control, and is the perfect solution for comparison with CAD data, rapid prototyping, reverse engineering and 3D modeling of free-form surfaces. The scanning probe uses blue laser technology, which has a shorter wavelength than red or green lasers and provides better scanning results with higher fidelity. This means that even the finest details can be captured, as well as the ability to scan dark and shiny surfaces is significantly improved.

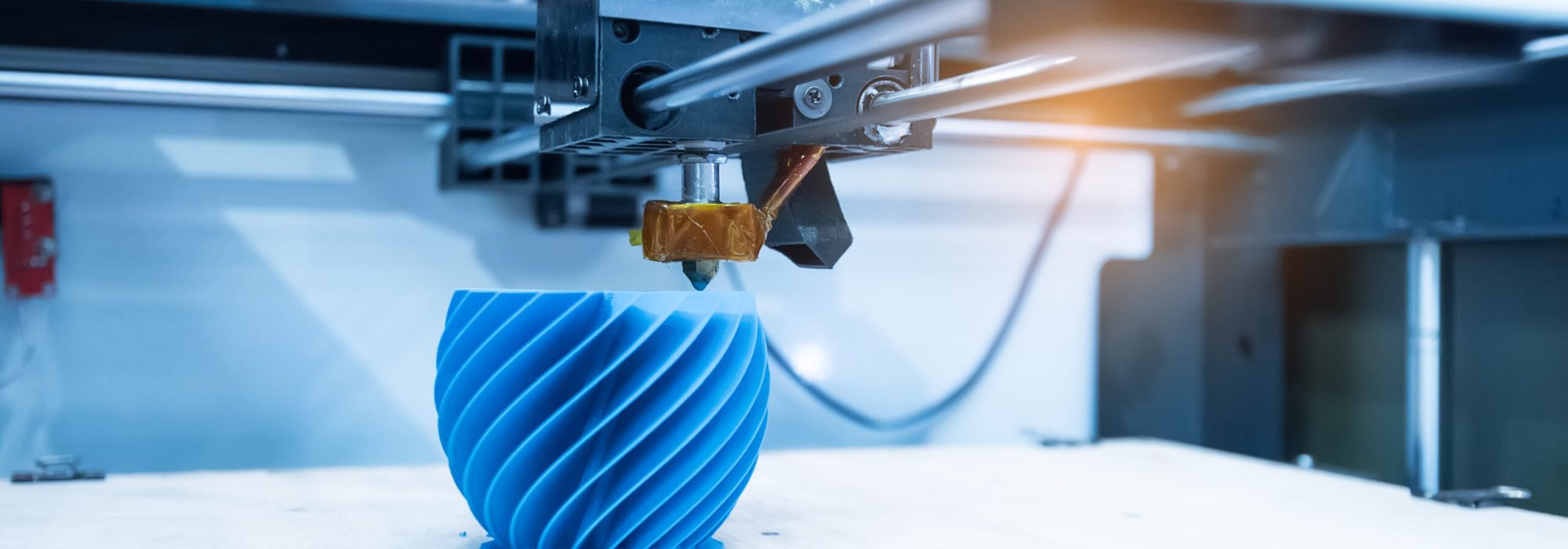

The Roboze ONE +400 extreme is a 3D printer based on the FDM (Fused Deposition Modeling) printing technique, in which the prototype is generated by melting and extruding a polymeric material that is in the form of a filament and that a printing nozzle deposits layer by layer in the print area.

The Roboze ONE +400 extreme is a 3D printer based on the FDM (Fused Deposition Modeling) printing technique, in which the prototype is generated by melting and extruding a polymeric material that is in the form of a filament and that a printing nozzle deposits layer by layer in the print area.

Materials:

Roboze One + 400 Xtreme processes a large variety of engineering polymers and super polymers. From aesthetic materials such as ULTRA-PLA and ABS, passing through flexible materials such as FLEX-TPU, up to super polymers such as PEEK and Carbon PEEK. Thanks to the extreme versatility and performance of super polymers, functional prototypes can be created for extremely different applications, accelerating the development and testing phase, reducing time and costs.

Other usable materials include: CARBON PA, CARBON PP, GLASS PA, PP, NYLON.

Dimensions and temperature of the printing bed: The Roboze One Xtreme printing bed, with a volume of 300 x 250 x 200 mm (xyz), reaches temperatures up to 150 °C (302 °F) which, together with vacuum technology, guarantees stability and perfect adhesion of the printed components throughout the process.

The EOS P396 is an industrial 3D printer, manufactured by the German company EOS, based on laser sintering printing technology (SLS), which is a 3D printing technique that uses a fiber laser to melt the raw material that is presented in the form of dust. Layer by layer 3D objects with excellent mechanical properties and high dimensional accuracy are built. The system is open, and allows you to fine-tune printing processes for different polymeric-based materials always reduced to powder.

The EOS P396 is an industrial 3D printer, manufactured by the German company EOS, based on laser sintering printing technology (SLS), which is a 3D printing technique that uses a fiber laser to melt the raw material that is presented in the form of dust. Layer by layer 3D objects with excellent mechanical properties and high dimensional accuracy are built. The system is open, and allows you to fine-tune printing processes for different polymeric-based materials always reduced to powder.

Materials: the EOS P396 printer allows a wide choice of polyamide-based materials, i.e.: PA 1101, PA 1102 black, PA 2200, PA 2201, PA 2210 FR, PrimePart FR (PA 2241 FR), PA 3200 GF, Alumide, EOS TPU 1301, PP 1101, PrimeCast 101, ALM FR-106, ALM HP 11-30, ALM PA 640 GSL